Hygienic Steam Systems

Hygienic Steam

When referring to "Steam Cleaning", it is often more "Hygienic/Clean Steam" than system steam.

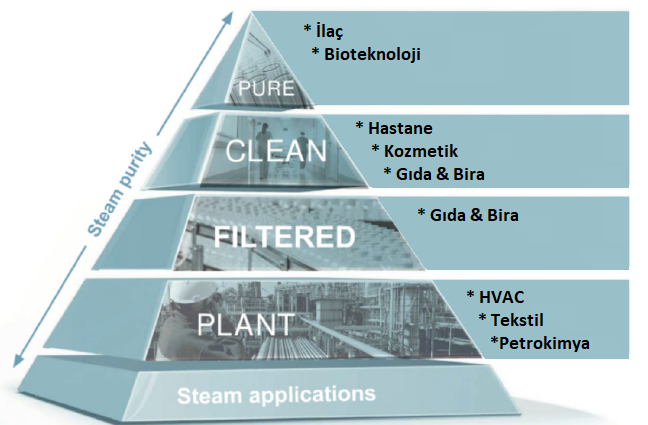

This is generally divided into 4 different categories:

System Steam - Standardized FDA approved boiler chemicals are used in steam produced in a conventional boiler with a typical water treatment. The tubing is standard carbon steel, or sometimes even black tubing, cast iron. All condensate is recovered.

System Steam - Standardized FDA approved boiler chemicals are used in steam produced in a conventional boiler with a typical water treatment. The tubing is standard carbon steel, or sometimes even black tubing, cast iron. All condensate is recovered.

Filtered Steam - Filtered to remove condensate and solid particles from the steam produced in a conventional boiler.

FDA approved chemicals are used in standard boilers.

If the tubing is standard carbon steel or black iron, it should be changed to 316 Stainless Steel.

All condensate is recovered.

Hygienic/Clean Steam - The flow of non-superheated steam to the steam generator is steam produced from distilled or deionized water or a reverse osmosis system.

All materials, components and tubing are 316 L Stainless Steel.

Rarely, condensate is recovered. The condensate is generally sent to a settling tank and then the water is treated.

Pure Steam - WFI for steam injection of non-condensed water where distilled or non-ionized pyrogen-free (medical term meaning non-bacterial) water still produces a multiple effect.

All materials, components and tubing are 316 L Stainless Steel.

Hygienic Steam

Clean Steam; It is used for sterilization, vacuuming, humidification and heating processes in Food, Pharmaceuticals, Cosmetics and Hospital establishments. Since the steam used in these processes must meet the hygiene norms, Clean Steam Production is provided with Secondary Clean Steam Generators suitable for sterile steam conditions.

Hygienic Steam Advantages

In terms of permanence; Pure Steam if the produced product comes into contact with blood; If it is in contact with the stomach and it is a medicine type, Clean Steam should be used, and if it is a food type, Hygienic Steam should be used.

In terms of permanence; Pure Steam if the produced product comes into contact with blood; If it is in contact with the stomach and it is a medicine type, Clean Steam should be used, and if it is a food type, Hygienic Steam should be used.

It would be much less costly to produce all three types of steam in a secondary generator with plant-steam produced in a steam generator, rather than directly in a boiler.

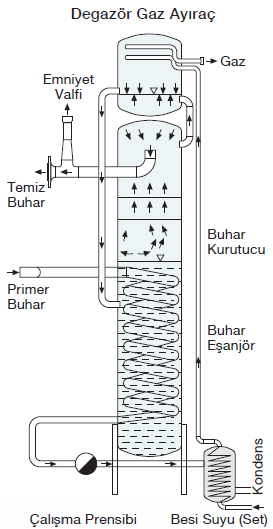

Working Principles of Hygienic Steam System

Material: Stainless Steel (AISI 316 Ti)

Material: Stainless Steel (AISI 316 Ti)

Function: Creating clean steam quality by using the steam heat exchanger as primary heating energy for high steam demands.

Design: The unit consists of clean steam tank, heat exchanger, on the chassis, pumps, valves, level controls and control panel. The unit is pre-wired and piped.

It has been tested by passing through hydrostatic tests. It is mounted on a structural steel base and delivered as a fully packaged unit with a simple connection for assembly and use.

Dimensions, capacities, inlet and outlet connections will be designed according to customer requirements. Also, single tanks are available on request.

Conditions: Standard operating pressures from 1 to 5 bar (g) 250 kg / h - 4,000 kg / h capacities Higher pressure ratios and capacities are available on request.

Flange Standards: acc. up to DIN EN 1092-1, PN6 / 16 / 40

Standards: The product fully complies with the requirements of the European Pressure Equipment Directive 97/23 / EC and bears the CE mark.

Hygienic Steam Usage Areas

While system steam is excellent for heat transfer applications in industries such as petrochemicals or pulp and paper, food and pharmaceutical companies should use filtered steam to a minimum or use clean steam to eliminate the risk of contamination.

Pure steam is the highest grade option and is required in pharmaceutical and biotechnology applications.

Hygienic Steam Price

Who Should Prefer Hygienic Steam?

Clean and pure Steam; It is used for sterilization, vacuuming, humidification and heating processes in Food, Pharmaceuticals, Cosmetics and Hospital establishments. Since the steam used in these processes must meet the hygiene norms, Clean Steam Generation is provided by Secondary Clean Steam Generators in accordance with sterile steam conditions.

Hygienic Steam System

Properties:

• Complete Stainless Steel (1715/316L) Manufacturing

• Plate or Tubular type Construction

• Wide Capacity (150-4,000 kg/h unit) Range

• Spiral Heat Exchanger

• Pump Feeding Station

• Steam Generation Module

• Deaerator (Gas Separation) Module

• Steam Dryer Cell

• Automatic Blowdown Module

• Thermal Body Insulation